Reducing volatile organic compounds (VOCs), which can cause air pollution, has become one of the issues seen as serious for the global environment. In the United States and Europe, regulations on VOCs began at around 1990. Also, in automobile manufacturing, one of Japan's main export industries, a certain degree of impermeability was made mandatory for tubes that convey liquid fuels and their evaporative emissions.

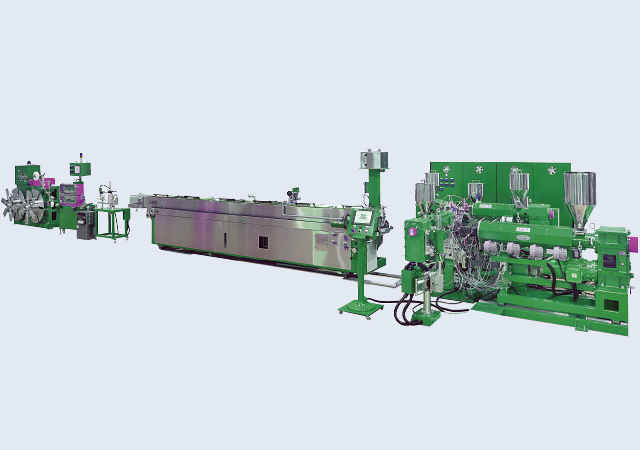

Against that backdrop, in 1980, PLA GIKEN CO., LTD. started selling multi-layer tube manufacturing equipment jointly developed with major automobile and raw material manufacturers.

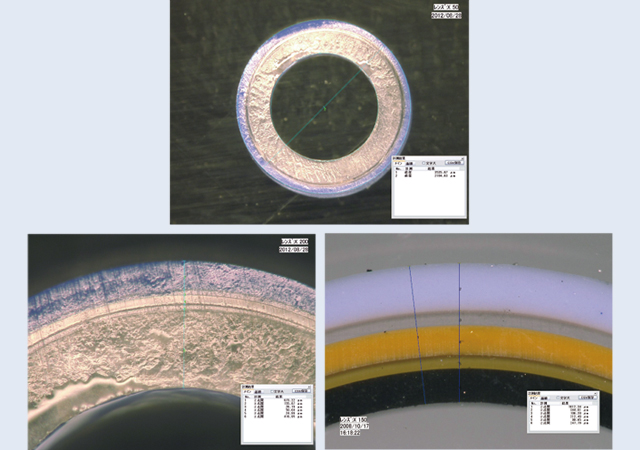

These machines are capable of co-extruding resins with different functions, including gas-impermeability, into multi-layer tube structures, such as in what is known as “'six- resins and six- layers'.” Our share of the above tubing line in the domestic market has reached about 70%. From a position behind the scenes, we are supporting the overseas expansion of Japanese automobile-related companies.